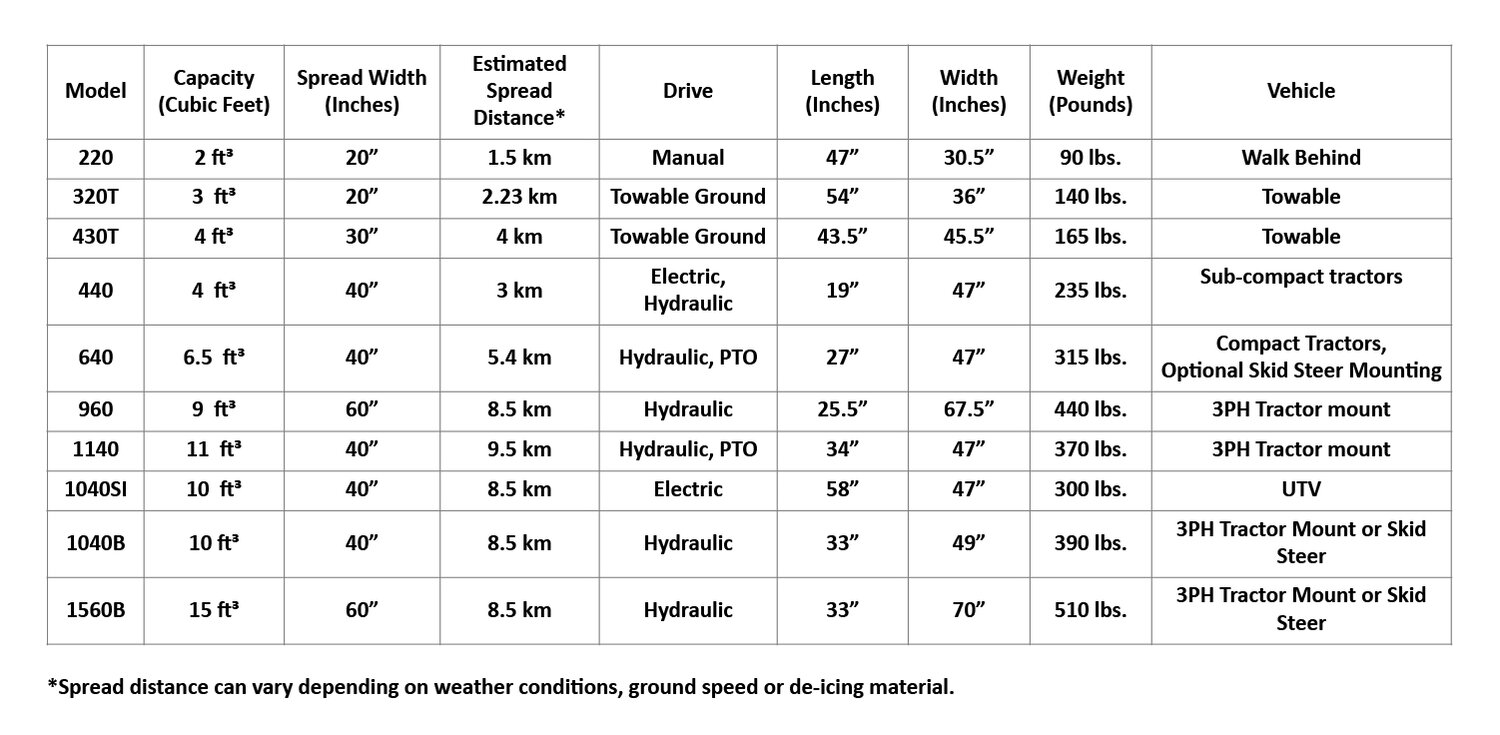

Bauman Model 440

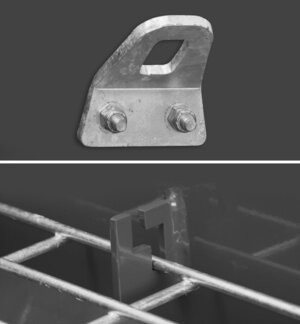

The model 440 comes in Electric or Hydraulic drives. The 440 is designed for sub-compact tractors and requires a hitch bracket. The hitch bracket required is dependent on the tractor and is sold separately. The optional mounting brackets include:

|

Specifications [applicable to 440E & 440H] :

|

|

|

Sealed Bearings

|

|

Spread Pattern

Spread Pattern |

|

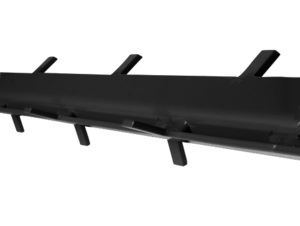

Finger Bar

|

|

Salt / Sand Drum

The rotating distributor drums spread de-icing material in an even and consistent cross hatch pattern. De-icing material can then "creep" and spread out which results in an efficient use of material. |

|

Agitator Bar

The agitator bar rotates in the hopper to help keep salt and sand from bridging or clumping. The bar ensures the material passes through to the drum and then to the ground for an even application. |

|

12 Volt 1/4 hp DC Electric Motor

The 12 Volt 1/4 hp DC electric motor and reducer drives the 440E. The epoxy paint protects the unit from salt brine/slushy environment. |

|

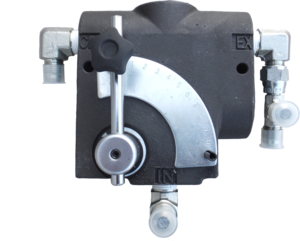

Tension Lever Assembly

The assembly regulates the rate of flow for different types of material (i.e.: fine sand vs coarse salt). The lever allows for fine tuning of the rate of flow of material. |

|

12 Volt 1/4 hp DC Electric Motor

The 12 Volt 1/4 hp DC electric motor and reducer drives the 440E. The epoxy paint protects the unit from salt brine/slushy environment. |

|

12 Volt 1/4 hp DC Electric Motor

The 12 Volt 1/4 hp DC electric motor and reducer drives the 440E. The epoxy paint protects the unit from salt brine/slushy environment. |

|

12 Volt 1/4 hp DC Electric Motor

The 12 Volt 1/4 hp DC electric motor and reducer drives the 440E. The epoxy paint protects the unit from salt brine/slushy environment. |

|

12 Volt 1/4 hp DC Electric Motor

The 12 Volt 1/4 hp DC electric motor and reducer drives the 440E. The epoxy paint protects the unit from salt brine/slushy environment. |