CLASSIC - CABLE CONTROLS

Reliability and simply use. Standard on all machines Classic.

Hydraulic reach mowers TP SeriesThe new TP Reach Mower generation is designed to deliver superior performance and durability compared to industry standards. The TP series models are available in the 5.1 m, 6.1 and 6.6 m outreach versions and offer a wide range of accessories and options that increase versatility and allow users to perfectly meet their work needs. Designed for farmers, medium-sized farms and local vegetation maintenance operators, the new TP reach mowers generation are of a heavy duty design with reliable cast iron pumps and motor. |

|

Max horizontal reach 15'9" |

| MACHINE | |

| Floating Head system |

|

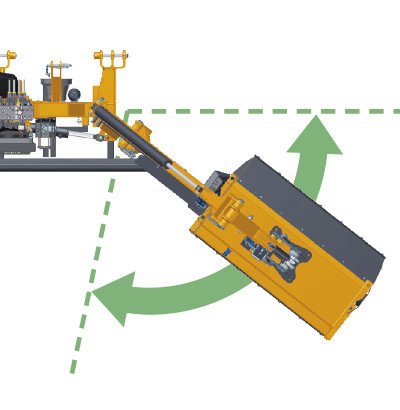

| Power slew | 115° |

| Pivoting bracket |

|

| Pressurized oil tank | 36 gal |

| Drop forged arm brackets |

|

| Drop forged flail head linkages |

|

| Oil cooler in Alluminum with thermostat | Optional |

| Light kit | Optional |

| HYDRAULIC SYSTEM | |

| Totally independent hydraulic system |

|

| Gear hydraulic system |

|

| ATT/4 sliding braket |

|

| Cast iron hydraulic pump servicing the rotor |

|

| Cast iron hydraulic motor |

|

| FLAIL HEAD | |

| Double skin |

|

| “OVERLAP” with double rows spiral rotor |

|

| Adjustable rear roller |

|

| Front and rear abrasion resistant guard for flail head |

|

| SAFETY | |

| Block valves to lock the pivoting bracket during transfer |

|

| Kit to avoid arm overturn | Mechanical |

| BRACKETS | |

| Stabilizers | Optional |

| Delta bracket | Optional |

Reliability and simply use. Standard on all machines Classic.

|

Max horizontal reach 15'9" |

| MACHINE | |

| Floating Head system |

|

| Power slew | 115° |

| Pivoting bracket |

|

| Pressurized oil tank | 36 gal |

| Drop forged arm brackets |

|

| Drop forged flail head linkages |

|

| Oil cooler in Alluminum with thermostat |

|

| Light kit | Optional |

| HYDRAULIC SYSTEM | |

| Totally independent hydraulic system |

|

| Gear hydraulic system |

|

| ATT/4 sliding braket |

|

| Cast iron hydraulic pump servicing the rotor |

|

| Cast iron hydraulic motor |

|

| FLAIL HEAD | |

| Double skin |

|

| “OVERLAP” with double rows spiral rotor |

|

| Adjustable rear roller |

|

| Front and rear abrasion resistant guard for flail head |

|

| SAFETY | |

| Block valves to lock the pivoting bracket during transfer |

|

| Kit to avoid arm overturn | Mechanical |

| BRACKETS | |

| Stabilizers | Optional |

| Delta bracket | Optional |

The EP Tronic control allows for easy portability of the cab control thanks to a light joystick and the lack of hydraulic hoses. The joystick is connected with an electrical cable to a control unit mounted on the distributor valves. The action is precise for cross movements of the first and second booms. The rotation direction of the rotor is controlled by electric switches on the console.

|

Max horizontal reach 19'5" |

Reliability and simply use. Standard on all machines Classic.

| MACHINE | |

| Floating Head system |

|

| Power slew | 115° |

| Pivoting bracket |

|

| Pressurized oil tank | 36 gal |

| Drop forged arm brackets |

|

| Drop forged flail head linkages |

|

| Oil cooler in Alluminum with thermostat | Optional |

| Light kit | Optional |

| HYDRAULIC SYSTEM | |

| Totally independent hydraulic system |

|

| Gear hydraulic system |

|

| ATT/4 sliding braket |

|

| Cast iron hydraulic pump servicing the rotor |

|

| Cast iron hydraulic motor |

|

| FLAIL HEAD | |

| Double skin |

|

| “OVERLAP” with double rows spiral rotor |

|

| Adjustable rear roller |

|

| Front and rear abrasion resistant guard for flail head |

|

| SAFETY | |

| Block valves to lock the pivoting bracket during transfer |

|

| Kit to avoid arm overturn | Mechanical |

| BRACKETS | |

| Stabilizers | Optional |

| Delta bracket | Optional |

|

Max horizontal reach 15'9" |

The EP Tronic control allows for easy portability of the cab control thanks to a light joystick and the lack of hydraulic hoses. The joystick is connected with an electrical cable to a control unit mounted on the distributor valves. The action is precise for cross movements of the first and second booms. The rotation direction of the rotor is controlled by electric switches on the console.

| MACHINE | |

| Floating Head system |

|

| Power slew | 115° |

| Pivoting bracket |

|

| Pressurized oil tank | 36 gal |

| Drop forged arm brackets |

|

| Drop forged flail head linkages |

|

| Oil cooler in Alluminum with thermostat |

|

| Light kit | Optional |

| HYDRAULIC SYSTEM | |

| Totally independent hydraulic system |

|

| Gear hydraulic system |

|

| ATT/4 sliding braket |

|

| Cast iron hydraulic pump servicing the rotor |

|

| Cast iron hydraulic motor |

|

| FLAIL HEAD | |

| Double skin |

|

| “OVERLAP” with double rows spiral rotor |

|

| Adjustable rear roller |

|

| Front and rear abrasion resistant guard for flail head |

|

| SAFETY | |

| Block valves to lock the pivoting bracket during transfer |

|

| Kit to avoid arm overturn | Mechanical |

| BRACKETS | |

| Stabilizers | Optional |

| Delta bracket | Optional |

Reversible Rotor by cable, Standard equipment on all reach mowers.

(lift float on the 1st arm by accumulator) Permits the engagement and disengagement of the lift float on the 1st arm.

Automatic roll-over protection when the first arm exceeds 90° in vertical position.

In consideration of the stress the reach mowers are subjected to during work, Ferri developed a new concept of frame, called «DELTA BOX» made of two sheet walls, which are laser-cut and joined with formed steel. The whole is welded on a robotized system; the structural design achieved is extremely light weight and strong.

Hydraulic breakaway system on power slew ram through a max. relief valve (protection of arms in case of hitting against obstacles).

Flail head suitable for reach mowers with gear hydraulic system and cast iron motor with direct drive. “OVERLAP” rotor with 2 spiral rows.

Cutting width: 3’11”

Weight: 463 lbs

Max cutting diameter: 1 3/4’’

Cutter bar

Cutting width: 51’’

Max cutting diameter: 3 1/4’’

Cutter bar

Working width: 87’’

Max cutting diameter: 3 1/4’’

Ditch cleaner.

Working width: 18’’

Cutter bar for hedges.

Working width: 59’’

Max cutting diameter: 1/2’’

Cutter bar for hedges

Working width: 59’’

Max cutting diameter: 1/2’’

Blower recommended in works along roads in order to clean the pavement and ground from the debris.

Airflow output: 90mc/min